how to calibrate a tensile testing machine|utm calibration : dealers To follow the accuracy-driven approach it is necessary to calibrate the tensile strength tester from time to time. Let us take a look at how the calibration process is performed. Performing Calibration Test on Tensile Strength . Resultado da Nada de ficar próximo das entradas e saídas dos parques do acampamento, para evitares mais uma vez a movimentação e barulho durante os horários de descanso. : sem pedras, ou material que possa aleijar. Acompanha a lista do material essencial para acampar. Se precisares apenas de carregar os .

{plog:ftitle_list}

Resultado da Julia Amareno is on Facebook. Join Facebook to connect with Julia Amareno and others you may know. Facebook gives people the power to .

utm calibration

About This Videos Dear viewers, In this Videos i have showed you how to calibration tensile testing machine, tensile machine full calibration procedure like how to place load cell.Calibrating a tensile testing machine is crucial to ensure accurate and reliable measurements of the material's mechanical properties. Proper calibration enhances the quality of the .

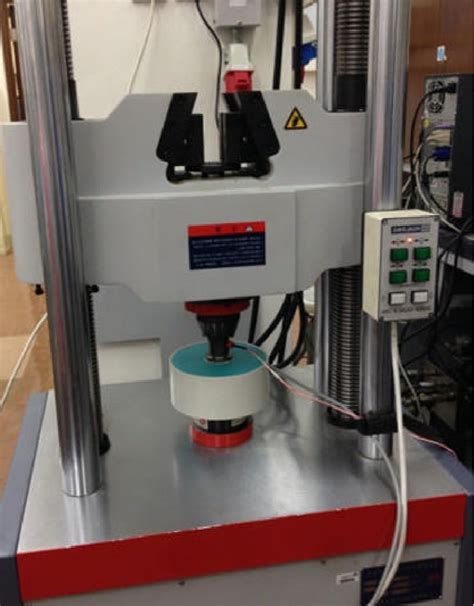

An ADMET engineer calibrates a universal testing machine. Image Credit: Admet Inc. ADMET provides a wide range of calibration and maintenance services for ADMET systems as well as those developed by .

bottled water taste test conclusion answer key

To follow the accuracy-driven approach it is necessary to calibrate the tensile strength tester from time to time. Let us take a look at how the calibration process is performed. Performing Calibration Test on Tensile Strength . The benefits of Tensile Testing Machine Calibration. Tensile tester machines provide data on the safety and integrity of materials, elements and those products that in reality help manufacturers assure their end .For instance, you can be certain that a tensile testing machine’s test findings are correct after it has been calibrated. It is comparable to accepted industry norms, in other words. . These are a few additional comparable standards that are used to calibrate universal testing equipment: Dynamic force ASTM E467; torque ASTM E2624; Essential components include a well-calibrated tensile testing machine, secure grips to firmly hold the sample, extensometers to measure elongation, and a data acquisition system to capture and analyze the force and deformation data. . and calibration, vendors can create a bridge of understanding, allowing for meaningful discussions and .

Maintenance and Calibration of Tensile Testing Machines Importance of Regular Calibration for Reliable Results . When you purchase an electronic tensile testing machine, it is usually calibrated by the manufacturer’s certified service technician as part of the installation procedure. After completing this initial calibration, you can be .Calibration of a universal testing machine (UTM) is the process of verifying and adjusting its performance to ensure accurate and reliable test results. This procedure involves comparing the machine's measurements to known standards and making necessary adjustments to ensure its accuracy and traceability, adhering to international standards like ASTM E2658, E2309, E4, .

Setting Up the Universal Testing Machine. Get your UTM ready for action—here is what you do: Power up the machine. Calibrate the Machine: Follow the manufacturer's guidelines to go through the procedure of calibrating a load cell. This allows the force measurement capacity so that the machine has the ability. Mount Specimen0.002% of applied force. The machine's deadweights are adjusted for local gravity, air density, and material density to apply the force accurately. The weights are used to calibrate the load cell, which may be used to calibrate and verify a testing machine 3. Compression and Tension Force Calibration

Connect the specimen to the tensile testing machine. Once the specimen is threaded to the bottom collet, place the other half jog the machine up to be able to thread the top to secure the specimen inside the unit. Install the extensometer on the specimen; Make sure there is some wiggle room in the specimen to record the best data, to avoid the . How Do Tensile Testing Machines Work? The way tensile testing machines operate is by securely clamping a sample and then applying uniaxial tensile force to it until the test specimen is broken or deformed. This can be done at a constant rate of elongation with either hydraulic or electromechanical systems.d) Open an existing test method by clicking on Test and choose which method you want to use. You must use an existing test method, you cannot create one as you go along. For creating a test method, please see the SOP “Creating a Test Method in Bluehill 3”. Step 2: Software Setup . a) Once inside the test method of choice, enter a sample name.The test results allow engineers and product designers to predict how a particular material will behave when in use. . We take the guesswork out of tensile tester calibration scheduling and budgeting by offering Preventative . whether it’s a weekly 10-point check or biannual equipment calibration, we meticulously create each PMA to fit .

Tensile tests are performed on universal testing machines, also known as tensile machines or tensile testing machines. These machines consists of a single or dual column frame equipped with a load cell, testing software, and application-specific grips and accessories such as extensometers.Universal testing machines come in a wide variety of force capacities and can .Whether you need a calibration for static or dynamic materials testing machines, pendulum impact testers, extrusion plastometers, HDT and Vicat testing instruments, drop weight testers, environmental chambers, hardness .

This calibration is carried out directly on your Drop Tower testing instrument, enabling you to be back up and testing in few hours, minimizing the downtime of your equipment. Read more about our On-Site Drop Tower Calibration .

Tensile testing with strain measurement techniques that can determine critical material properties including elastic modulus, tensile strength, elongation at break, and Poisson’s ratio. MTS provides testing systems, mechanical testing systems, simulation systems and sensing solutions to researchers, developers and manufacturers worldwide.

Whether the test force value is accurate or not is related to the sensor. After excluding problems such as operator errors, we can use a simple method to verify the accuracy of the tensile tester. The test speed calibration method of tensile testing machine. Tensile testing machine is a kind of precision mechanics testing instrument.Calibration of a universal testing machine entails verification of the accuracy of the system’s instruments responsible for obtaining force and displacement measurements. . (ASTM E2658 and E2309), strain and load rate (ASTM E2309), and measurement of tension, compression (ASTM E4), torque (ASTM E2624), and dynamic force (ASTM E467). . PDF | The technique adopted in calibrating Tensile Testing Machines is described. The method provides good accuracy and the procedure is simple. | Find, read and cite all the research you need on .The ASTM E4, ISO 7500-1 standards describe the fundamental conditions, requirements and verification of load cell calibrations for static, single-axis testing machines. They are used to ensure proper calibration and are highly relevant in a wide range of industries and for many different applications. The standards establish an important foundation for reliable test results.

Tensile testing machines are also commonly referred to as Universal Testing Machines—they can perform an extremely wide variety of measurements on practically any material. Tensile stresses can be applied to materials in various ways to determine the tensile shear adhesion and tear properties to name a few.i.e. Pull testing to the minimum tensile value. Destructive Pull Test. i.e. Pull testing to the breaking strength of the crimped connection. If we want to correctly calibrate our crimp tool, besides the dimensional calibration and the go / no-go gauges, the best way is to perform a tensile strength test to a number of samples of crimped joints .The tensile test is a test method within mechanical materials testing, used for the determination of material characteristics.Depending on the material, the test is used in accordance with the respective industry standard for determination of the yield strength, tensile strength, strain at break and other material properties.. In the tensile test a material specimen is strained until it .

Galdabini Universal Testing Machines can be calibrated by any force calibration professional. top of page. 1-978-882-1480 . How to Verify the Load Cell Calibration on a Universal Testing Machine . The setup is slightly different when calibrating in either tensile or compression as can be seen in the below pictures.Thank you for purchasing the AGS-X series AutoGraph testing machine. This instruction manual includes guidelines for installing the system, precautions that should be followed when using the system, and a description of relevant accessories and optional parts. . Test Jigs (1) Tensile Test Jig 1) Screw Type Flat Grips (1 set of upper and lower .

You should calibrate your machine’s displacement measuring system if any of the following apply to you: Displacement is critical to your testing needs and is reported in the test results. Use of an extensometer is impractical or impossible, and using crosshead displacement is an acceptable alternative.

bottled water taste test lab

22 de jan. de 2020 · Reprodução/TV Globo. Marcos (Romulo Estrela) e Paloma (Grazi Massafera) em cena da novela Bom Sucesso, da TV Globo. REDAÇÃO. Publicado em 22/1/2020 - 3h04. Quarta, 22/1 .

how to calibrate a tensile testing machine|utm calibration